Latest News

How can the life science industry be more environmentally friendly?

22 Apr, 20246 MinutesAs an industry that is positioned to bring value by providing products and services that con...

As an industry that is positioned to bring value by providing products and services that contribute towards the health of the public, the conversation around ecological sustainability tends to skip over the pharmaceutical industry. Sectors such as large-scale manufacturing, automotive, and agriculture battle constant public scrutiny over their sustainability practices, so how can the life sciences sector act to make its activities and outputs greener too?

Companies in the drug development space have long avoided their spot under the microscope when it comes to the environmental impact of their processes and practices, despite the fact the industry is responsible for more pollution than the automotive sector, one which is often under a hefty amount of scrutiny during climate discussions.

We’re in a time where sustainability and environmental consciousness is considered an important issue to almost 70% of the general population, and an organisation's response to the issue can have major implications on commercial success.

Reacting to the climate crisis and in response to public opinion, governments around the world are pledging their commitments and introducing policies that hope to tackle the effects of climate change – the same governments that play a major part in the regulation, approval, and distribution of the products that are critical to the bottom line of drug development firms – so the conversation around sustainability in pharma has never been more prevalent.

The environmental impact of pharmaceutical practices

When considering the environmental impact of the pharmaceutical sector, images of thick smoke and air pollution may not be the first thing that comes to mind, but the industry produces greenhouse gasses at a rate 13% higher than that of the automotive sector despite being a smaller sector.

A substantial number of emissions that come as a result of pharmaceutical development are during the clinical trial stages. Centralised trial designs that require employees to commute, patients to travel, deliveries related to products to take place, and the distribution of trial materials to occur, make for an energy-intensive period in the drug development cycle that contributes up to 14 tonnes of greenhouse gas emissions per employee.

Outside of trial design, waste produced during the manufacturing process presents its own environmental issues too. Studies have shown that poorly controlled disposal of waste products from drug manufacture have gone on to impact water pollution levels, leaving a potentially devastating effect on local ecosystems and the potential for resistant bacteria to form.

Challenging the current ways of working

Several pharmaceutical companies have encouraged sustainability within their own products and processes in recent years, setting internal targets and pledging green targets to which they’ll hold themselves accountable.

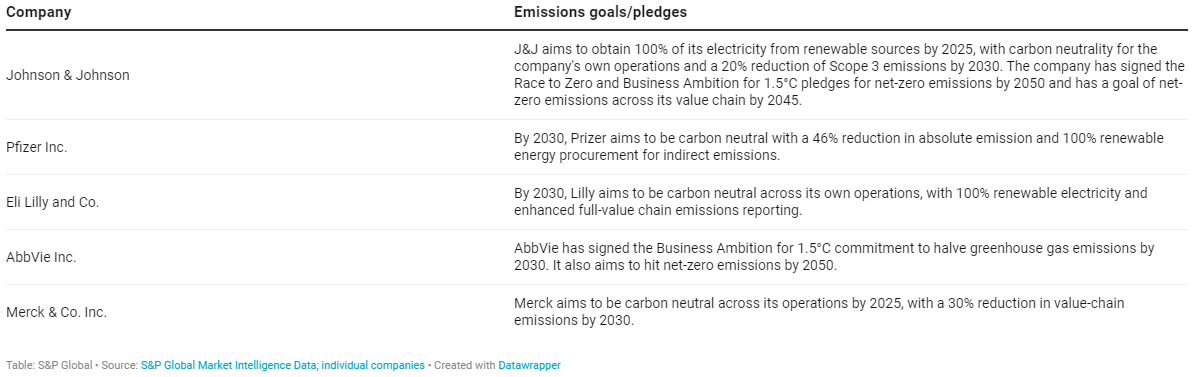

28% of the pharmaceutical sector (by market share) has joined the United Nations’ Race to Zero commitment to reach net-zero emissions by 2050, with giants J&J, Pfizer and Eli Lilly among those setting clear and measurable emissions goals, with deadlines alongside their environmental proposals.

The largest US biotech and pharmaceutical companies' net-zero carbon emissions goals

Committing to bold sustainability action is a promising first step, but whether the industry can deliver real change will be apparent in long-term changes to trial design, drug production and manufacturing efforts.

The pandemic has shown how technology and innovation can enhance trial design and allow trials to continue without the need for travel to and from a central trial site. Continuing to use such tech will allow for more decentralised trials to take place, make trials simpler and more efficient, and cut the level of energy needed for a clinical study to take place.

Tech can also be leveraged to improve efficiencies in the manufacturing process and lead to a reduction in waste materials that impact local environments. Effective modelling of pharmaceutical manufacturing chains can ensure the most effective use of materials and energy, and reduce the unnecessary bi-products created during drug production.

Sustainability as an opportunity

Pharmaceutical companies face a whole host of benefits in pledging greener processes and committing to sustainable practices, not least because the industry is a major polluter, and the future of our planet depends on the global effort to reduce emissions.

Societal attitudes towards big pharma are historically volatile, and while public opinion may have changed after the industry’s response to the Covid-19 pandemic, improving public relations is beneficial for any organisation dealing in public health. Communicating intent and showing action toward combatting emissions presents an opportunity to change public perception and further indicate an organisation’s commitment to tackle global issues.

From a commercial standpoint, aligning climate goals with that of the governments and local regulators that review drug and product submissions is only going to positively impact approval rates and the company’s bottom line.

Strong corporate environmental, social and governance programmes can also increase stock liquidity, as in recent years individuals and institutions have been investing heavily in corporations that demonstrate their ability to operate in an ethical and sustainable matter.

When it comes to seeing true sustainability in practice within the life sciences sector, we’re at the very beginning of the story.

With pledges and commitments laid out by major players, it’s clear the industry is akin to the benefits of a strong sustainability strategy. But, given the complexity involved in changing decades-old processes, it looks to be a long time before the environmental issues the industry contributes towards can be considered under control.